Cover Safe and Food Safe Sleeved Tubes protect spaces from the potential danger of smashed lights.

Why are sleeved tubes needed?

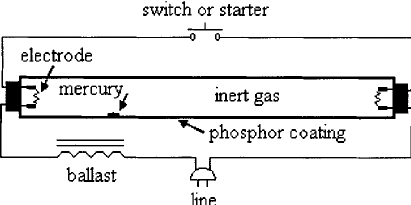

Fluorescent lamps contain Mercury, which can be a harmful substance when leaked into the air.

Fluorescent tubes are made with glass - plastic cannot be used as an alternative as it cannot contain the mercury and gas within. However, using glass increases the health and safety risk as glass has a delicate structure and a higher risk of shattering.

New regulations have set out to stop the high levels of amount of mercury in lamps which has been restricted to significantly lower than ever before in order to lower the health risk.

A ban on fluorescent lighting will follow in September 2023.

The delicate structure of fluorescent lamps can be dangerous and an even higher risk in environments such as schools, workplaces, kitchens and shops as glass can shatter, ending up in food and possibly injuring people.

When buying Fluorescent Tubes, shatterproof glass must be considered, especially in applications such as commercial kitchens and food manufacturers as venues must consider the regulations around contamination of food and glass control. Applications such as offices and workplaces need to have Shatterproof glass to ensure the safety of their employees.

What is the difference between Cover Safe and Food Safe?

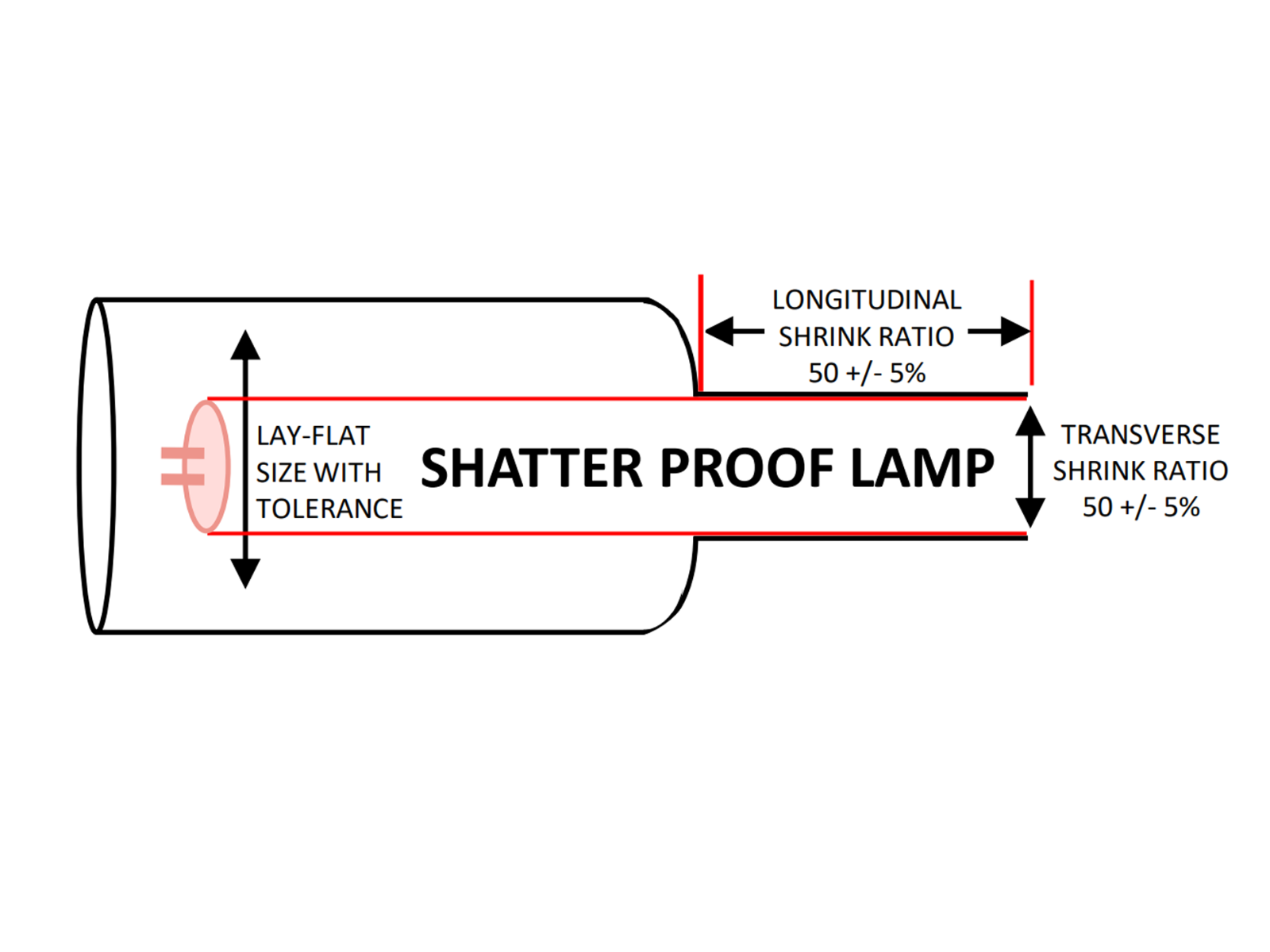

Cover Safe is a standard Polyethylene Terephthalate covering that is used to make the lamp shatterproof. This is used to ensure products meet UK health and safety standards for offices, schools, retail, etc.

However, this covering is not suitable for use in any food environments, including Food manufacturing, restaurants and cafés as the Food Standards Agency have stricter standards in place.

Food Safe is a thicker material which creates an even stronger layer on the outside making sure that if a glass lamp did break, it would stay intact and not contaminate any food below.

Does Northgate Lighting Offer Cover safe and Food Safe tubes?

Northgate Lighting manufacture in-house to deliver this service to our customers. The Northgate factory wrap the tube in either a Cover Safe or a Food Safe plastic covering, then heat the plastic up to 100℃ so that

it shrinks and wraps around to fit the lamp perfectly making sure to keep intact the properties of the lamp, ensuring that no light is lost in the process and that the product doesn’t lose any quality due to its new feature. The wrap also blocks out UV light.

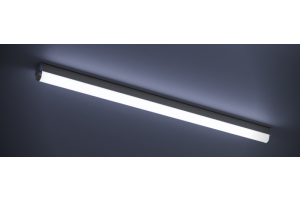

Although the majority of lamps that need this process are fluorescent some LEDs, that are made from glass will also need a covering as they impose a risk to health and will need to meet the IEC/ BS EN 61549 regulations. An alternative to this would be to find a substitute to glass such as LEDs with a plastic covering.

At Northgate we supply a wide range of range of LED tubes made with a polycarbonate tube - we recommend trying out the Bright Source range of LED Tubes! The polycarbonate tube also has the benefit of being Impact Resistant which is perfect for applications in kitchens and workplaces that need to meet safety regulations.